Printed circuit boards (PCBs) are the foundation of modern electronics. They’re found in everything from your phone to your car, and they play an essential role in our daily lives. But what’s really happening behind the scenes when you buy a PCB?

In this blog post, we’ll take you through each step of the process, from designing it to manufacturing it. By understanding how they are made, you can better understand how technology works and why it’s so important. So, whether you’re a tech enthusiast or just curious about how things work, read on to learn more about it.

What is a Printed Circuit Board?

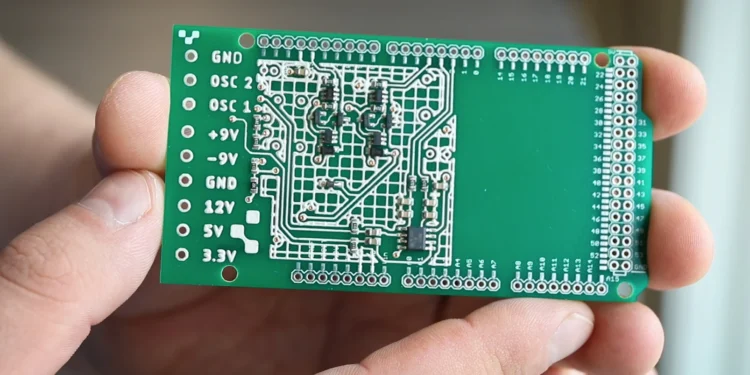

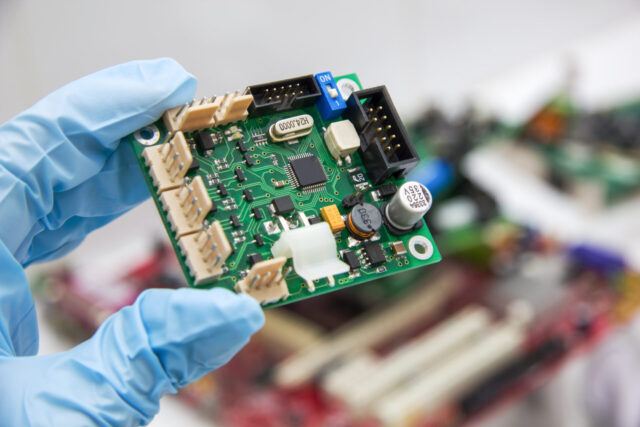

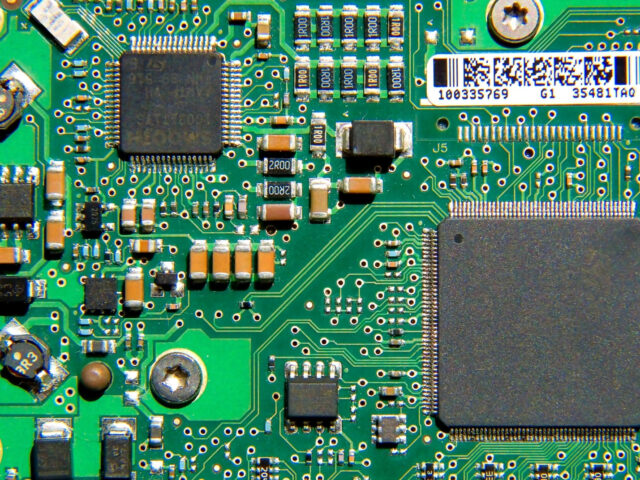

Printed circuit board is a critical component in modern electronics and it can be found in almost every device we use. PCBs are made up of layers of circuit boards that are stacked on top of each other. Each layer has different functions, and the entire board is connected together with wires and traces.

They are manufactured by a variety of methods, but the most common way to make them is called die-casting. Die-casting is a process where a mold is created out of plastic or metal. The mold will usually have cavities that represent the various parts of the PCB that will be cast onto it. Next, the plastic or metal plating is injected into the mold, and as it hardens, it creates shapes that represent the various parts of the PCB. The finished PCB will usually have multiple cavities on it, each representing one layer of the board.

After die-casting, it must be cleaned up before it can be assembled into devices. This involves removing any excess plastic or metal from around the cavities and borders, as well as sanding down any rough edges. Once everything looks clean and ready to go, assembly can begin.

One popular method for assembling them is called SMT (surface mount technology). SMT refers to circuits that are mounted on surfaces instead of inside a traditional package. SMT circuits are usually more compact and they can be mounted in a variety of different ways. This allows for a greater degree of flexibility when it comes to assembly, as well as increased reliability.

The Most Common PCB Manufacturing Problems and How to Avoid Them

PCB manufacturing is a highly complex and delicate process that requires careful attention to detail in order to produce reliable and accurate boards. Here are the most common PCB manufacturing problems and how to avoid them:

- Overtightening of screws can cause warping or distortion of the board.

- Oversized components can cause damage during assembly or printing, leading to faulty boards.

- Incorrectly-sized traces can create shorts or openings in the circuit, which can cause malfunctions or data loss.

- Failing to properly clean the tools, parts, and work area prior to each session can lead to contamination and ruined boards.

Wrapping Up

Printed circuit boards are one of the most important parts of any electronic device. In this 2024 guide, we’ll walk you through each step of the process by which a PCB is made. By following along, you’ll be able to create your own printed circuit boards and make sure that your devices always work correctly. So, start learning now and you’ll be well on your way to becoming an expert in PCBs!