Sheet metal bending is an essential skill for any fabricator. It’s a process that allows you to create custom pieces out of metal, plastic, and other materials. But what if you don’t have a machine? In this article, we will show you how to bend sheet metal without a machine using just your hands. It’s a skill that can be extremely useful in a wide variety of settings, from manufacturing to construction.

What is Sheet Metal Bending?

Bending sheet metal without a machine is possible with the use of hand tools and simple techniques. There are three main types of bends that can be made: convex, concave, and arc. Each type of bend has its own specific requirements, so it’s important to understand how each one works before you try it out.

- Convex bends are used to create curves in the metal. This is easiest to do by using a radius rule to create the desired curve. You can also use a bench vise or clamp to hold the piece in place while you bend it.

- Concave bends are used to shorten or lengthen pieces of metal. To make a concave bend, start by bending one end tight against the workbench and then gradually loosen the grip as you make the bend. Be sure to use a center vise or clamp to keep the metal in place while you’re making the bend.

- Arc bends are used most often when creating welds or other connections between two pieces of metal. To make an arc bend, start by laying one piece of metal on top of another and aligning the edges so that they’re parallel. Then put pressure on one end of each piece and slowly pull them toward each other until they form an arc.

Tools You’ll Need for Sheet Metal Bending

In order to bend sheet metal without a machine, you’ll need the right tools. There are a few essential pieces of equipment that will help you achieve the desired bends.

- Sheet metal bender: This is the most important tool you’ll need for bending sheet metal. Without it, you won’t be able to make any bends or tweaks to your pieces. The best brands have features like digital readouts and adjustable tension controls, which makes them perfect for precision work.

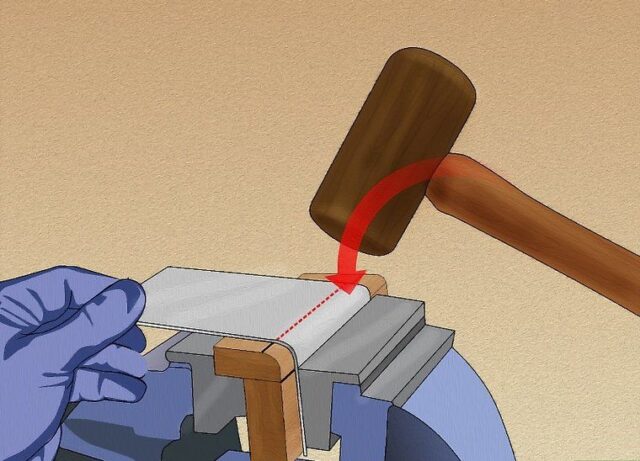

- Hammer: A standard hammer will suffice for most tasks, but if you’re looking to give your bender a bit more power, consider purchasing a hammer with a thicker head.

- Chisel: A chisel is helpful for shaping and trimming the edges of your metal sheets before bending them. It can also be used to cut through stubborn material without damaging the surface of the sheet metal.

- Sheet metal cutting mat: A good sheet metal cutting mat will make it easy to cut straight lines and curves. Make sure to choose one that’s lightweight and easy to move around so that you can position the piece you’re working on correctly on the mat.

In conclusion, bending sheet metal without a machine can be a difficult task, but with the right tips and techniques it can be easy to get the job done. By following these simple steps, you can successfully bend sheet metal without any trouble.