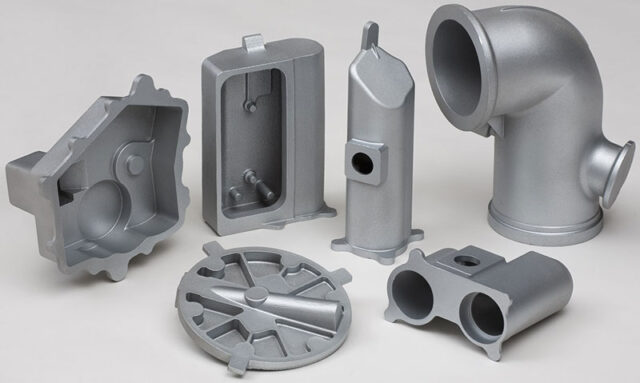

Investment casting is a process that’s often used in the aerospace and automotive industries. In short, it’s a way to create custom parts without resorting to traditional manufacturing methods. For those of you who are new to the process, or who just want to improve your design skills, here are four tips for investment casting design.

Investment Casting Basics

Investment casting is a manufacturing process that creates objects by depositing a solid material, usually metal, into a mold. The most common application for investment casting is the production of small objects like figurines and key chains.

There are a few things to keep in mind when designing an object using investment casting:

- Start with a design that is easily cast. Sacrifice detail for simplicity when creating your object’s model. The simpler the design, the easier it will be to cast.

- Use contrasting colors and textures to create visual interest. These elements will help draw the viewer’s attention to your object and make it more visually appealing.

- Make sure your model is detailed enough for the final product, but not so complex that it becomes difficult or time-consuming to cast.

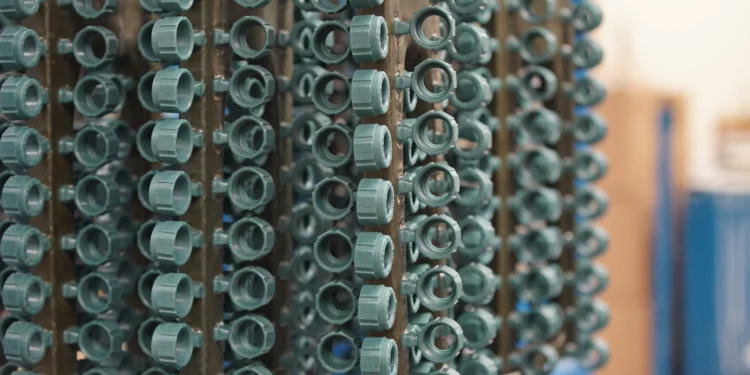

- Use standard mold-making techniques when creating your investment casting models. This will ensure that your models are durable and can be produced at high volumes without costing too much money in materials or labor.

Mold Design for Investment Casting

Investment casting is a manufacturing process that creates objects from a solid metal by forcing the metal into a mold. The mold is typically made of plastic or other material and is often customized to fit the object being created.

There are many factors to consider when designing an investment cast part, including:

– The shape of the part

– The size of the part

– The material used for the part

– The decorative features that will be included on the part

– The temperature at which the object will be produced

– The speed at which the object will be produced

Here are some tips for designing investment cast parts:

– Start with a rough idea of what you want your part to look like. Use renders or sketches to create a preliminary model of your part. This will help you develop better ideas for how to format and design your mold.

– Consider how you want your finished product to look. Is it important to have accurate detail or do you want a more stylized appearance? Decide before you begin creating your mold whether digital or manual drafting tools are appropriate for your project.

– Choose a material that will suit your design and production needs. Some metals such as aluminum can be cast relatively easily in cold environments, while others such as brass may be better suited for hot extraction processes. Consider also the finish that you would like to achieve on your finished product. Do you want it polished or matte?

Conclusion

When starting out in investment casting design, it’s important to be aware of the different processes involved and learn about each one. This article has outlined some key tips for beginners so that you can start making informed decisions when designing your castings. By following these guidelines, you’ll be on your way to becoming a successful investment caster.