When you think about technology, printed circuit boards (PCBs) likely come to mind. PCBs are a crucial part of every modern technology, and without them, many industries would grind to a halt. In this blog post, we’re going to explore some of the industries that rely on PCBs and how they’ve been able to stay afloat in the face of technological advancements. We’ll also discuss some of the challenges that these industries face and how you can help them overcome them.

What are Printed Circuit Boards?

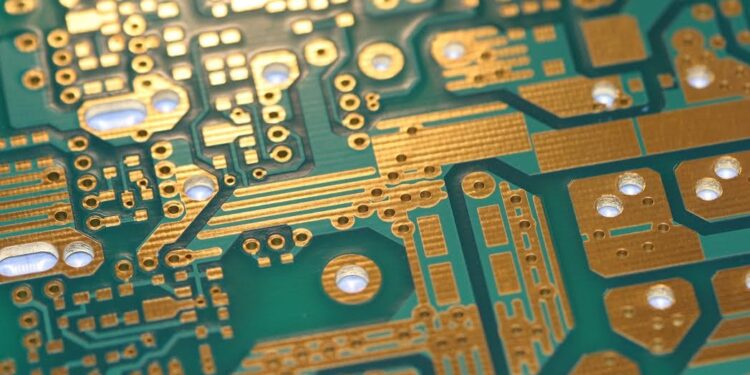

Printed circuit board is a component used in electronics and telecommunications. They are thin sheets of metal with layers of transparent plastic or other materials laminated to one another. They are cut into individual pieces that are then soldered or glued together to create a device.

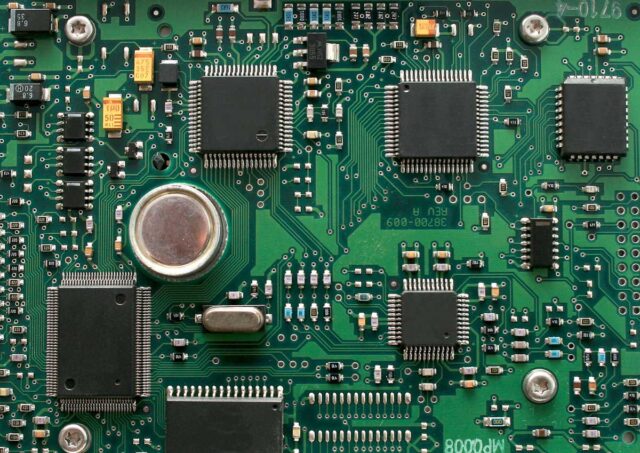

They are used in a variety of devices, including phones, computers, and appliances. They play an important role in connecting electronic components together and help protect these components from damage.

Printed circuit boards are often made using electroplating, also known as PCB printing. This process involves coating the entire surface of the PCB with a layer of metal alloy. The thickness of the layer is determined by how much material the printer can pump out per minute.

There are many different types of PCBs, each with its own unique features and benefits. If you’re planning on starting a business that makes or uses electronic products, it’s important to know about the different types of printed circuit boards available and the best ways to design them.

Industries That Rely On Printed Circuit Boards

The printing and coating of PCBs is a major industry in its own right. The manufacturing and sale of printed circuit boards account for over $22 billion in annual sales.

They are also used in a wide variety of other industries, including:

- Telecommunications

- Aircraft engineering

- Medical devices

- Automotive engineering

- Consumer electronics

PCBs in the Automotive Industry

PCBs have been in use in automotive applications for so many years, and are still a popular choice today. There are many reasons why they are a popular choice for automotive applications:

– PCBs are lightweight, which makes them easy to install and remove.

– They’re durable and resistant to corrosion.

– They’re easy to maintain and upgrade.

– They can be customized to fit specific needs.

– They’re often less expensive than other types of electronics.

Despite these benefits, there are some challenges that need to be taken into account when using PCBs in automotive applications:

– They can be sensitive to vibration and shock. This can lead to malfunctioning or even damage to the electronics.

– The electrical connections between the components on a PCB can become damaged if they’re subjected to high temperatures or humidity levels.

– It’s important to ensure that the design of the PCB is robust enough to withstand environmental conditions and frequent contact with grease, oil, water, and other contaminants.

Wrapping Up

PCBs play an important role in many industries, and are often sensitive to environmental conditions and vibration. Fortunately, there are many robust PCB designs available that are able to withstand these challenges. If you’re planning on starting a business that uses printed circuit boards, it’s important to understand these factors and design your products accordingly.